RESISTANCE TEMPERATURE DETECTOR – The incorporates pure metals or certain

alloys that increase in resistance as temperature increases and conversely. Rtd

is basically a temperature transducer which converts the temperature into

resistance the output of the rtd is ohm.

rtd

has linear resistance temperature characteristics they have positive

temperature coefficient

types of rtd- generally here some types of rtd is given –

(1)

PT100

(2)

PT150

(3)

PT200

In our plant we are using only PT100

, PT100 means it shows the 100Ω resistance at zero degree

Celsius

Temperature

in °C |

||||||

−50

|

80.31

|

|||||

−45

|

82.29

|

|||||

−40

|

84.27

|

|||||

−35

|

86.25

|

|||||

−30

|

88.22

|

|||||

−25

|

90.19

|

|||||

−20

|

92.16

|

|||||

−15

|

94.12

|

|||||

−5

|

98.04

|

|||||

0

|

100.00

|

|||||

5

|

101.95

|

|||||

10

|

103.90

|

|||||

15

|

105.85

|

|||||

20

|

107.79

|

|||||

25

|

109.73

|

|||||

30

|

111.67

|

|||||

35

|

113.61

|

|||||

40

|

115.54

|

|||||

45

|

117.47

|

|||||

50

|

119.40

|

|||||

55

|

121.32

|

|||||

60

|

123.24

|

|||||

65

|

125.16

|

|||||

70

|

127.07

|

|||||

75

|

128.98

|

|||||

80

|

130.89

|

|||||

85

|

132.80

|

|||||

90

|

134.70

|

|||||

95

|

136.60

|

|||||

100

|

138.50

|

|||||

105

|

140.39

|

|||||

110

|

142.29

|

|||||

150

|

157.31

|

|||||

200

|

175.84

|

We should not use rtd at above 850⁰c above

850⁰c the linearity of rtd will ended and reading will be inaccurate. In our we

are using rtd at 550⁰c range only

Wiring configurations

Two-wire configuration

The simplest resistance thermometer configuration uses

two wires. It is only used when high accuracy is not required, as the

resistance of the connecting wires is added to that of the sensor, leading to

errors of measurement.

Three-wire configuration

In order to minimize the effects of the lead

resistances, a three-wire configuration can be used. Using this method the two

leads to the sensor are on adjoining arms. There is a lead resistance in each

arm of the bridge so that the resistance is cancelled out, so long as the two

lead resistances are accurately the same.

Four-wire configuration

The four-wire resistance thermometer configuration

increases the accuracy and reliability of the resistance being measured: the

resistance error due to lead wire resistance is zero. In the diagram above a

standard two-terminal RTD is used with another pair of wires to form an

additional loop that cancels out the lead resistance.

Range setting of rtd – to calibrate a rtd the

standard method is that take an ice bath reference for 0⁰c and arrange a

furnace for required higher according to use actually it is impracticable so we

purchase only calibrated rtd and set the range according to requirement we can

set the range of rtd by decade resistance box

Actually it is the calibration of indicator in

terms of temperature whatever temperature is sensed it is determined by rtd in

terms of resistance only because the output of the rtd is ohm but we see direct

temperature reading through indicator

First disconnect the rtd to the transmitter

then give 100Ω through DRB to the transmitter this time the scanner should show

zero if this value does not come press the zero button showing (here two button

first zero and another span )after that give resistance according to maximum

process temperature you want like you to 200 degree C give 175.84Ω if the

scanner does not show 200 then press span button and adjust

Pneumatic actuator

A Pneumatic actuator mainly consists

of a piston, a cylinder, and valves or ports. The piston is covered by a diaphragm, or seal,

which keeps the air in the upper portion of the cylinder, allowing air pressure

to force the diaphragm downward, moving the piston underneath, which in turn

moves the valve stem, which is linked to the internal parts of the actuator

Pneumatic cylinders (sometimes known as air cylinders) are mechanical devices which use the power of compressed gas

to produce a force in a reciprocating linear motion.

Like hydraulic

cylinders, something forces a piston to move in the desired direction. The

piston is a disc or cylinder, and the piston rod transfers the force it

develops to the object to be moved. Engineers prefer to use pneumatics sometime

because they are quieter, cleaner, and do not require large amounts of space

for fluid storage.

Because the operating fluid is a gas, leakage from a

pneumatic cylinder will not drip out and contaminate the surroundings, making

pneumatics more desirable where cleanliness is a requirement.

Pneumatic

actuator is basically a 5/2 solenoid valve where has 5 port two for outlet two

for exhaust and one for air inlet if one

coil uses we can operate the piston either fully open or fully closed condition

. if we want to stop the

piston at a certain desire position like 30% or 40% we have to use double

solenoid .

In our jamul plant ther are many

places where pnumatic actuator are going to use like in packers in cement silo to air slide here electric

motor damper actuator and pnumatic actuator both are present but in case if electric

motor doesn’t work we can operate the pnumatic actuator

Electric motor hydraulic

actuator –

in electric motor hydraulic actuator there is a motor which circulates the the

oil its function is similar like pneumatic actuator only difference hrere in

place of air oil is used

Figure - electric motor hydraulic actuator

Electric motor control damper

actuator – it

has 3 phase induction motor its operate the lever this actuator has primary and

secondary gear secondary gear also known as worm gear at front side there is

indicator which shows the position of damper at the back side wheel and handle

is given if we want to operate the actuator manually then push the handle

clockwise this thing bypasses the motor now we can easily set the position of

damper as per requirement through the wheel in this actuator there is an

advantage that we can adjust the damper at 30% , 40% etc but in

most pneumatic actuator(with single solenoid

coil) we operates only either fully open or fully close condition

Electric motor damper actuator has 6 limit

switch as described further

2 limit switch for full open (1 for retendency

in case failure)

2 limit switch for full close condition (1 for

retendency in case failure)

1 for open torque (when we open the damper for

flow if there is obstruction like material jamming or some material struck

around)

1 for close torque (when we close the damper if there is obstruction like

material jamming or some material struck around foreign material coming )

Thermocouple- A thermocouple is a type of temperature

sensor, which is made by joining two

Dissimilar metals at one end. The joined end

is referred to as the HOT JUNCTION.

The other end of these dissimilar metals is

referred to as the COLD END or COLD

JUNCTION. The cold junction is actually formed

at the last point of thermocouple

Material certain combinations of metals must

be used to make up the thermocouple pairs.

If

there is a difference in temperature between the hot junction and cold

junction, a

Small voltage is created. This voltage is

referred to as an EMF (electro-motive force)

And can be measured and in turn used to

indicate temperature.

The

voltage created by a thermocouple is extremely small and is measured in terms

of

Millivolts (one millivolt is equal to one

thousandth of a volt). In fact, the human body

Creates a larger millivolt signal than a

thermocouple. The output of thermocouple is mV

Polarity checking of thermocouple take a multimeter it has two lead red and

black and our thermocouple has also 2 lead connect one lead of thermocouple to

multimeter red lead and another to another one if the multimeter shows +ve

reading the terminal connected to red is positive terminal of thermocouple and

if shows –ve the terminal connected to red is negative terminal of thermocouple

Thermocouple connection to

hart calibrater

COLD JUNCTION COMPENSATION -

the last point of thermocouple material is

known as the cold

junction. The amount of output the t/c

produces is determined by the difference

between the hot junction and the cold junction

temperatures. The cold junction

temperature must be known to accurately

determine the temperature.

Lets

look at the following examples;

If we

had a thermocouple in a heat treat furnace and wanted to know what

temperature it was in that furnace, we could

attach a voltmeter to the cold junction

and measure the voltage.

Let’s

say that the furnace is operating at 1000 deg.C. and it is 100 deg. C at the

cool end of the T/C. Since we said that a T/C

measures the difference between the

hot and cold junctions, our formula would be:

1000

(hot junction) - 100 (cold junction) = 900 deg. C.

There

seems to be a problem since we said that the furnace was at 1000 deg. F.

This brings us to COLD JUNCTION COMPENSATION.

COLD

JUNCTION COMPENSATION is usually done automatically by the measuring

instrument. The instrument measures the

temperature at the cold junction and adds it

back to the equation.

1000

(hot junction) - 100 (cold junction) = 900 deg. C + 100 deg. C

(cold

junction temp) = 1000 deg C

This

way the instrument indicates the actual temperature of the hot junction.

This COLD JUNCTION compensator is usually

located at the terminals on the back

of the indicating instrument and you must

maintain T/C material all the way to this

point.

In our plant we use hart for this, connection

with hart to t/c is shown in figure hart

is also uses for range setting

For compensation we give any certain voltage through

the multimeter to t/c voltage depends on the atmospheric temperature consider 1.5mV . we use 4-20mA system if the

multimeter shows some rating above than 4mA now then reverse the lead multimeter will show some reading less than

4mA here set the point with 0 deg C

Actually

every thermocouple designed for reference at 0 deg C but our atmosphere is at

30deg C thats why we needed cold

junction compensation

For a

thermocouple to function properly, there must be no other metals used between

the hot junction and the cold junction. If

wire is needed to connect the T/C to the

indicating instrument, the lead wire must be

made of the same material as the T/C.

Thermocouple types-

Type E: The Type E thermocouple has a Chromel

(Nickel-10% Chromium)

positive leg and a Constantan (Nickel- 45%

Copper) negative leg. Type E has a

temperature range of -330 to 1600F, has the

highest EMF Vs temperature values of

all the commonly used thermocouples, and can

be used at sub-zero temperatures.

Type E thermocouples can be used in oxidizing

or inert atmospheres, and should not

be used in sulfurous atmospheres, in a vacuum

or in low oxygen environments where

selective oxidation will occur. The color code

for TYPE E wire is purple and red.

Type J:

The Type J thermocouple has an Iron positive leg and a Constantan

negative leg. Type J thermocouples can be used

in vacuum, oxidizing, reducing and

inert atmospheres. Due to the oxidation

(rusting) problems associated with the iron

leg, care must be used when using this

thermocouple type in oxidizing environments

above 1000F. The temperature range for Type J

is 32 to 1400F and it has a wire

color code of white and red. THERMOCOUPLE

THEORY

Type K:

The Type K thermocouple has a Chromel positive leg and an Alumel

(Nickel- 5% Aluminum and Silicon) negative

leg. Type K is recommended for use

in oxidizing and completely inert

environments. Because it’s oxidation resistance is

better than Types E, J, and T they find widest

use at temperatures above 1000F.

Type K, like Type E should not be used in

sulfurous atmospheres, in a vacuum or in

low oxygen environments where selective

oxidation will occur. The temperature

range for Type K is -330 to 2300F and it’s

wire color code is yellow and red.

Type N: The Type N thermocouple has a Nicrosil

(Nickel-14% Chromium- 1.5%

Silicon) positive leg and a Nisil (Nickel-

4.5% Silicon- .1% Magnesium) negative

leg. Type N is very similar to TYPE K but is

less susceptible to selective oxidation

effects. Type N should not be used in a vacuum

or in reducing atmospheres in an

unsheathed condition. The temperature range is

32-2300 deg F and its wire color code

is orange and red.

Type T:

The Type T thermocouple has a Copper positive leg and a Constantan

negative leg. Type T thermocouples can be used

in oxidizing, reducing or inert

atmospheres, except the copper leg restricts

their use in air or oxidizing environments

to 700F or below. The temperature range for

Type T is -330 to 700F and it’s wire

color code is blue and red.

Optocoupler:

Optocoupler is a one type of

device which is used to work as a isolator between two frequency.

We are using in cement plant

different type of electronic circuit. In that electronic ckt.we are using in

different type of micro-processor.in that micro processer for doing work

require a oscillator ckt. in that oscillator we are giving ac power supply then

oscillator ckt generate frequency in mega-hz.so different type of company make

a different type of oscillator whose generate different frequency.

Construction of opto coupler:-1.LED

2. PHOTO TRANSMITTER

When we provide power supply to

the LED, it emits the light .this light is provide on the base of photo

transmitter. Then photo transmitter generates current this current is directly

proportional to the light.LED and photo transmitter are not electrically

connected. Only connected each other by the light. That device frequency not

interrupted each other because there is not induction effect.

From example we can see

optocoupler is a one type of isolator between two frequency . and from this

example we can understand that different type of instrument connected of each

other which is given same output (4-20mA)but its frequency is different like

2Khz,3kHz etc..But that frequency not interrupted each other .because there is

installed optocoupler . if we will not installed optocoupler then each frequency interrupt each other and this

disturbance is called “radio frequency disturbance” . For that disturbance

removed we use optocoupler

Optocoupler is a device and

isolator is a system. In weigh feeder and VFD very necessary to use isolator.

From one isolator we can take

1,2,3 etc. Output.

Magnetic separator:-type

of magnetic separator

1. permanent magnet

2. electromagnet

3. magnetic separator

1. Permanent magnet:-by manual cleaning

We know this is a permanent.

Which is suspense above the belt conveyor. When any ferrous material come with

the lime stone, then it is attracted by the permanent magnet .after some it

clean by manually or as per schedule.

In Jamul plant this device is installed crusher` s no 1 above the

belt conveyor.

2. Electromagnet: - it can be both type manually

or automatic

In this magnetic separator a

temporary magnet happens. This is suspended above the belt conveyor. In this

magnetic separator have a coil. When we provide electric supply in this

separator then emf induced in this coil. This supply can happen 110V AC or dc,

24 V DC OR 230V AC etc. when ferrous material come with the lime stone then

electro magnet attract this material. It material clean by manually or

automatic as par schedule. For automatic, this electromagnet`s interlocking

with the belt conveyor when conveyor`s supply off then material fall down on the belt then clean the belt.

This device is installed in Jamul plant crusher no 2 above the

belt conveyor

3. Magnetic separator:- in this system one electromagnet

suspense above the belt conveyor. In this electromagnet around a small belt

installed with the help of idler. This belt is rotate around the electromagnet.

For giving belt rotation one motor is installed. This motor gives supply

separately. When we provide supply on the electromagnet then emf is generate on

his coil. When ferrous material come with the material (i.e. coal, limestone

etc.).Then it is attract by the electromagnet. Rotating belt this material

separate out of the belt . So material is separate from the main material

This separation is two types

1.

Inline magnetic separator

2.

Cross belt magnetic separator

1.

Cross belt magnetic

separator:-this type of separator installed above the belt conveyor on The cross

condition.

2. Inline magnetic separator:-this

type of magnetic separator is installed above belt conveyor in the condition of

inline.

Metal detector:- for the detect metal from the material.

Generally this is installed above

the belt conveyor. These devices have a wooden frame which has up side and down

side one- one coil. Upper coil called transmitting coil and dipper coil called

receiving coil. One control box installed in these devices which have two PCB

(printed ckt board & Amplifier. One

PCB (printed ckt board) &Amplifier for transmitting coil. And One PCB

(printed ckt board) for receiving coil. Control box connect with the panel box

by the four core cable. Four core cable describe

1. Red for +12 volt

2. Black for -12 volt

3. blue- 0(zero)

4. yellow- for signal

In the penal box different type

of device like power supply card, logic card, sensitivity probe, transformer

etc. On the panel box door have 3 probes-

1.

for on/off

2.

for reset

3.

for acknowledgment

Working:-when we provide 24 volt dc on the

power supply card then supply goes to the PCB amplifier ckt. After that PCB

have a oscillator ckt. That oscillator generates 18-25 KHz frequency for

transmitting coil & same like this 16-18 KHz frequency for receiving coil.

So between transmitting coil & receiving coil something become a balance

magnetic field. In that time if we check voltage between zeros and signal then

we will find something -0.5 to -1 volt. Now if metal come with the limestone

(material) which will be disturbed of magnetic field then emf will be generate

around the metal which will take power from the supply. Then current will

disturb after that this current goes to the amplifier and amplifier, amplified

this current and signal send to the comparator which have on the logic card.

Then comparator will comparison between signals and o/p send the signal to

traic. After that traic operate relay

then belt will stop. After that attainder

will come and he push the

acknowledgement button then metal detector sense the signal after that

attainder clean the metal then he push reset button then metal detector again

start.

Remember always that metal`s come

in running condition then metal detector work if metal come and stop below

metal detector then metal detector will not work.

In Jamul metal detector installed both on the crusher`s belt

conveyor etc.

This is detecting 10 mm size and

more than 10mm.on the sensitivity probe 6 no cut by the potentiometer. If we

set sensitivity 1 then metal detector`s ability poor if we set sensitivity 6 than metal detector`s ability very high

&fast.

ADMITTANCE LEVEL LIMIT SWITCH

Ø When

material level in silo goes beyond a preset limit this switch will activated

and close the filling of silo

Ø When

material levels will high sensitivity indicator will reach high position and so

a GREEN LED will lights and after a

time delay RED LED will lights (COVERED TIME DELAY).

Ø When

material level will low sensitivity indicator will reach low position and after

a time delay (UNCOVERED TIME DELAY) RED LED will turn off.

Ø FAIL SAFE MODE:

If it is high(HI) then operator will acknowledge whether material level goes

high or power cut and vice versa.

Controller of

admittance level limit switch as shown in below:

GREEN

Sensor part of admittance limit switch

CO MONITERING SYSTEM

There are

two analyzer. Samples are coming form 3 points for each analyzer.

There are 3 points A, B & C in CO

gas analyzer. At a time one is working and one is cleaning [To remove dust

which accumulated during sampling] by air purge and another is in rest condition.

The sequence of A, B & C selected by

a logo PLC.

The sample gas comes to cooler

(Temperature should in between 1-4°c to maintain gas flow).From cooler it comes

to paper filter and through a pump it comes to GAS ANALYZER (Through a flow

meter).

If CO gas will high, then there will be

a risk of explosion because CO gas is self-burning.

DISTRIBUTED CONTROL SYSTEM(DCS) AND PROGRAMMABLE LOGIC CONTROLLER(PLC)

The

differences between DCS and PLC are: DCS (Distributed Control System) is a

CONTROL SYSTEM that works using several controllers and coordinates the work of

all these controllers. Each controller is handling a separate plant. This

controller is referred to the PLC.

PLC is an

automation tool. Automation developed to reduce human effort. In every industry

there is a process (Manufacturing chain).This manufacturing chain consists of a

list of activities. To do these activities we have to operate electrical and

other kinds of energy. We can operate this either by man power or by machine.

In ancient

days we have to monitor instruments on the location. Later we did it in one

room. But it creates a complicated hardware. And ultimately software has

developed and starts improving.PLC designed then and it completely consists of

logic.

To run a

process there is a system, sequence and this sequence consists of a list of

activities. We chart out these

activities in software and make logic (program, sequence). To run this logic

certain inputs are required. These inputs are coming from field and some inputs

we generate. According to this inputs logic runs and generate outputs. This

output finally goes to its destination. To catch inputs and fetch outputs to

its destination we require a number of input /output modules (they are

expandable but limited). [AI, AO, DI, DO]

By the

above arrangement (1) Hardware (2) Trouble-shooting become easy.

To interact with the running process runs by

PLC, we have to interface (communicate) with PLC. Human machine interface (HMI)

makes this opportunity.

PLC

capacities are two types. I/O capacity and MEMORY capacity. When this capacity

limits out, thinking has started to find new technology.

In

petrochemical and oil refinery industries number of AI,AO greater than DI,DO so

no of data processing greater than others which require large time, so speed of

processing slow(Analogue signal is time variant so no of bits are high BUT

Digital signals are 2-bit signals ) because burden on CPU increases. In that

situation conventional PLCs are unable to carry the process. Thus desired

output cannot get at desired time.

To overcome

this problem we use discrete (individual) controlling system. But we give a

common platform to this discrete controlling, and termed it as DCS. Thus burden

on CPU decreases.

In this

centralised system every controller connected in a common place, since they are

working individually they controlled by this common platform.

RETARDANCY: In critical places we use greater than one

similar unit.

e.g., we

use two power supplies just for back up. Here a battery is used to store edited

programs if both of power supply gets failed.

Two cables are used to connect CPU

with HMI.

RETARDANCY=

DEPENDANCY

In DCS system there are

Digital Inputs (switches, contacts {pressure switch, limit switch etc})

Digital Outputs (Solenoid valve coil supply {In Pneumatic Actuator}

etc) HI or LO

Analogue Inputs (Pressure Transmitter, Vibration Transmitter, Temperature Transmitter, VFD etc)

Analogue Outputs (Electro-hydraulic Actuator {force coil}, Weigh-Feeder TPH setting etc) 4-

20mA

CONTROLLER4=RAW MILL 1, 2&3CONTROLLER3= CEMENT MILL 4, 5&6 + CEMENT MILL7, 8 WEIGH-FEEDER (ON-OFF COMMAND)

M=CPU OF EACH

CONTROLLER (PROGRAMS ARE STORED IN THE MEMORY

OF THIS CPU AND THE INPUTS FROM FIELD COME HERE THROUGH DI&AI. ACCORDING TO PROGRAM

OUTPUT GENERATE AND GOES TO FIELD THROUGH AO&DO)

LIMIT

SWITCH

A limit switch is a switch operated by the motion

of a machine part or presence of an object. They are used for control of a

machine, as safety interlocks.

e.g., a person passing through the way beside the belt conveyor,

now if his shirt gets trapped in moving belt, then he

will pull a rope beside it termed as pull cord. This pull cord will move a

lever, and this lever will do a changeover contact thus an interlock will

operate to trip the belt.

PRESSURE

SWITCH

A pressure

switch is a form of switch that closes an electrical contact when a certain set pressure has been reached on its

input. The switch may be designed to make contact either on pressure rise or on

pressure fall.

In our plant

pressure switch is used to protect gear box. For lubrication in gear box the

oil pressure should be 1 kg/cm2.If it goes below 1kg/cm2 ,then

motor will trip by the changeover switch. To set this pressure a knob is

located at the upper side of the switch.

VIBRATING

FORK LEVEL LIMIT SWITCH

Tines

of vibrating fork in mechanical vibration of a resonance frequency of 80HZ by

piezoelectric materials. When service material covers the tines, they cause

damping of vibration .This stoppage of vibration sensed by electronic circuitry

& the signal after processing is used to operate a relay. Potential free

contacts of relay are available for alarm or control.

When tines

are free from material the fork starts vibration again and the relay contracts

revert to previous position.

DIFFERANTIAL PRESSURE TRANSMITTER:

WHAT IS DP TRANSMITTER?

This equipment will sense the

difference in pressure between two ports and produce an output signal with

reference to a calibrated pressure range.

CONSTRUCTION & WORKING OF DP

TRANSMITTER:

CONSTRUCTION:

The DP TRANSMITTER

has two parts. The upper part is transmitter and lower part is transducer.

|

|

Transducer:

- in this part it has two ports. One is high port and other one

is low port. In centre capsule is there, which contains carbon powder. It also

have diaphragm at both the sides of ports. These diaphragms are act as plates

of capacitor and the capsule (carbon powder) act as dielectric medium.

The

output of this transducer is CAPACITANCE.

This output gives to transmitter through a wire.

Transmitter:

- the transmitter is electronics based. It contains

microprocessor. It has 4 terminals, 2 for supply and 2 for output to DCS. It

also has security switch, fail safe mode, zero and span adjustment switch. The

output of transmitter is in MILLI AMPERE

(4 to 20m amps). It contains three

cards

Ø

Power card: -

Ø

CPU ( or memory card): -

Ø

Calibration card: -

WORKING: -

When high port is connected to at high pressure side

and low port is connected to low pressure side or kept open in atmospheric. The

diaphragms are act as plates of capacitor and the capsule (carbon powder) act

as dielectric medium. The both diaphragms are compresses the carbon powder

(dielectric medium). How much difference will takes place according to that the

output of the transducer e.i capacitance also changes. Our final output of the

transmitter (e.i 4 to 20m amps) also changes.

RANGE SETTING: -

We are setting the range of the transmitter by using

the zero adjustment switch and span adjustment switch.

ZERO ADJUSTMENT SWITCH: -

this switch is used to set the transmitter value at 0 pressures. To set this,

we are keeping the both port open, at this pressure the output is should be

4mA. If it is not 4mA then press the zero

adjustment switches for 5seconds.

SPAN

ADJUSTMENT SWITCH: - by using this switch we are setting

the value of the transmitter at MAX pressure. To set this value we giving the

max pressure at high port side and the output of transmitter should be show the

20mA. If not press the span adjustment

switch for 5seconds and the output will set at 20mA. Then also not come

repeat the same.

SECURITY

SWITCH: - it has two positions ON and OFF.

After setting this value we should be make security switch ON. Because no one can change the settings of the

Transmitter Before doing range settings we should keep the security switch at

OFF position.

FAIL SAFE

MODE: - this is also having two positions LOW and HIGH.

Ø

LOW

POSITION: - in this condition the relay is in de-energised at

normal position. When power is cut-off, the relay will energise and normally

close (NC) contact is used, it will open and it gives indication to DCS.

Ø

HIGH

POSITION: - in this condition the relay is in energised at normal

condition. The NO contact of the relay is used. When power is cut-off, the

relay will de-energise and normally open (NO) contact will comes to its

original position and it gives indication to DCS.

The

HIGH position is safer than the LOW position.

The above functions of the

transmitter are shown in below figure.

PROXIMITY SENSOR

A proximity

sensor is a sensor able to detect the presence of nearby objects

without any physical contact.

A proximity sensor often emits an electromagnetic field or a beam of electromagnetic

radiation (infrared, for instance), and looks for changes in the field or return signal. The object being sensed is

often referred to as the proximity sensor's target. Different proximity sensor

targets demand different sensors. For example, a capacitive photoelectric sensor might be suitable for a plastic target; an inductive proximity sensor always requires a metal target.

Inductive & Capacitive

Their operating principle is based on a high frequency oscillator that creates a field in the close surroundings of the sensing surface. The presence of a metallic object (inductive) or any material (capacitive) in the operating area causes a change of the oscillation amplitude. The rise or fall of such oscillation

is

identified by a threshold circuit that changes the output state of the sensor.

The operating distance of the sensor depends on the actuator's shape and size

and is strictly linked to the nature of the material . A screw placed on the

back of the capacitive sensor allows regulation of the operating distance. This

sensitivity regulation is useful in applications, such as detection of full

containers and non-detection of empty containers. Their operating principle is based on a high frequency oscillator that creates a field in the close surroundings of the sensing surface. The presence of a metallic object (inductive) or any material (capacitive) in the operating area causes a change of the oscillation amplitude. The rise or fall of such oscillation

Photoelectric

These sensors use light sensitive elements to detect objects and are made up of an emitter (light source) and a receiver. Three types of photoelectric sensors are available. Direct Reflection - emitter and receiver are housed together and uses the light reflected directly off the object for detection. Reflection with Reflector - emitter and receiver are housed together and requires a reflector. An object is detected when it interrupts the light beam between the sensor and reflector. Thru Beam - emitter and receiver are housed separately and detects an object when it interrupts the light beam between the emitter and receiver.

These sensors use light sensitive elements to detect objects and are made up of an emitter (light source) and a receiver. Three types of photoelectric sensors are available. Direct Reflection - emitter and receiver are housed together and uses the light reflected directly off the object for detection. Reflection with Reflector - emitter and receiver are housed together and requires a reflector. An object is detected when it interrupts the light beam between the sensor and reflector. Thru Beam - emitter and receiver are housed separately and detects an object when it interrupts the light beam between the emitter and receiver.

Magnetic

Magnetic sensors are actuated by the presence of a permanent magnet. Their operating principle is based on the use of reed contacts, which consist of two low reluctance ferro-magnetic reeds enclosed in glass bulbs containing inert gas. The reciprocal attraction of both reeds in the presence of a magnetic field, due to magnetic induction, establishes an electrical contact. |

|

Load cell

A load

cell is a transducer that is used to convert a force into an electrical signal. This conversion is indirect and happens in two

stages. Through a mechanical arrangement, the force being sensed deforms a strain gauge. The strain gauge measures the deformation (strain) as an electrical signal, because the strain

changes the effective electrical resistance of the wire.

How

Does It Work?

Wheatstone Bridge

A load

cell usually consists of four strain gauges in a Wheatstone bridge configuration. Load cells of one strain gauge

(quarter bridge) or two strain gauges (half bridge) are also available.[1] The electrical signal output is typically in the

order of a few milli volts and requires amplification by an instrumentation

amplifier before it can be used. The output of the

transducer can be scaled to calculate the force applied to the transducer.

OUTOUT OF

LOAD CELL = milli volt/ volt

LOAD CELL

Beam

Load Cell Model Z6

·

The HBM Z6 bending beam load cell is the primary weighing

components for industrial scales. In addition to its exceptional accuracy (accuracy class according to OIML R60)

the Z6 load cell is well suited to withstand even

harsh manufacturing Welded on metal bellow

·

Load cells and

mounting aids entirely made from stainless material

·

Six-wire circuit

·

Nominal load: 5 kg / 10 kg /20 kg / 50 kg / 100 kg / 200 kg

/ 500 kg / 1t

·

Material: Stainless steel

APPLICATION

In Packer

After Row Mill Silo for weighing

the weight of Row Mill before feeding to Pre Heater

Single Point Table Top Load Cell

HOW DOES IT WORK

During a measurement, weight acts on the load

cell'smetal spring element and

causes elastic deformation.

This strain (positive or negative) is converted

into an electrical signal by a strain

gauge (SG) installed on the

spring element. The simplest type of load cell is a bending beam with a strain

gauge. Often the (mandatory) basic components, i.e. spring element and strain

gauge are complemented with additional

elements (housing, sealing

elements, etc.) protecting the strain gauge elements.

FEATURES

·

Moisture

Proof sealing harsh Environment

·

Very

sensitive can measure even small change in load

·

Nominal

load 20kg , 50kg, 100kg

APPLICATION

·

used in weigh feeder of 50 kg

COMPRESION

TYPE LOAD CELL

With rated loads ranging

from 60kg to 500t compression load cells are applicable for a variety of

applications.

APPLICATION

·

In weigh bridge we are

using this type of load cell

·

In hoppers

LEVEL

TRANSMITTER

Level

transmitter is a device which is used to measure the level of the material in

silo, bucket elevator boot. One type of level transmitter is Ultrasonic Wave Level Transmitter.

ULTRASONICWAVE

LEVEL TRANSMITTER:

-

Inside this unit

it has both wave transmitter and wave receiver.

Wave is transmitted (blue arrow) by the wave transmitter and this wave

is goes down and hit the material and reflects. This reflected wave (red arrow)

is received by the wave receiver. The time required to reach again wave to

receiver, based on this time we are calculating the ullage portion and

subtracts this portion from total height.

In display unit we

have to enter some parameter like

Ø

Height of silo.

Ø

What we want FILLAGE or ULLAGE.

FILLAGE= Total Height – Ullage

ULLAGE= Display unit

Ø

Density of the material.

Ø

Finesse of the material.

Ø

Material name.

Ø

Medium of the transmission like air, water, moisture etc…

Ø

Ambient temperature.

Solenoid valve

Solenoid valve is used for pneumatic operation.

There is three type of the solenoid valve

we using in the Jamul cement works .

·

3/2 solenoid valve

·

5/2 solenoid valve

·

2/2 solenoid valve

2/2 SOLENOID VALVE

2/2 Solenoid valve is used for air purging.

There is two port in this type of solenoid 1 for air inlet and 1 for air

outlet. In bag filter we are using this for air purging.

When give the 4-20 mA to the coil the coil get energised and it

pull the plunger and due to this the air get exhausted from the bottom valve

and diaphragm get loose and a space get created and from this air will go inside

and do the air purging of bags

3/2

SOLENOID VALVE

3/2 solenoid valve is used for aeration. There is three ports

in it. Two outlet of the air and one for

inlet of the air. As the coil charges the air flow through the outlet 2 and

when it we get discharge is goes through outlet 1 and vice versa

5/2 SOLENOID VALVE

5/2

solenoid valve used for piston

operation. There is 5 ports in the 5/2

solenoid valve.

1 port for air

inlet, 2 for air outlet, 2 for exhaust

Let take the

example we want to movie the piston to the right side then we give the air

comes from the air inlet and due to the coil operation the air goes from the

outlet 1 at same time when piston moves towards right side at the same time the

compressed air in the piston cylinder get exhausted from the outlet2 this

exhausted air is goes outwards by the ex 2

When we want to

move the piston toward left side at that time the air comes from the inlet to

the outlet 2 than it exhaust from the

outlet 1 than it exhaust through the ex 1

SOUND SENSOR ( FOLAPHONE)

·

The Folaphone system

measures the “sound level” of the mill by means of the special Folaphone

microphone and amplifier. The resulting output from the “microphone amplifier”

is called the “sound level” signal.

·

The purpose of the signal

treatment, in the wall cabinet, is to make a signal that is proportional to the

material filling in the ball mill

·

The Folaphone uses the raw

mill shell as the diaphragm so it measure only the sound of the row mill it

will not get effected by sound of the surrounding

TACHOMETER

Tachometer

is the device used to measure the speed of the motor there are two type of

tachometer we are using in the Jamul cement works

v Analogue tachometer

v Digital tachometer

ANALOUGE

TACHOMETER

Analogue

tachometer is a simple small DC GENERATOR whose shaft coupled to the main drive shaft to measure the speed of the main

drive

WORKING

In

the analogue tachometer the main drive shaft is coupled to the dc generator

shaft as the main drive rotes the dc generator rotor also rotates and

proportional to the speed of main drive the dc generator also generates the

output voltage this output voltage is calibrated and speed of the drive is

determined

v We are using analogue

tachometer in Jamul for measurement of kiln main drive rpm

DIGITAL

TACHOMETER

In

digital tachometer a disc is installed with the rotor shaft as shown in the as

the shaft rotates the disc also rotate and in front the disc a proximity sensor

is installed and as the teeth of the disc comes in front of the sensor it

generates the output pulse by counting this output pulse the speed of the drive

is measures

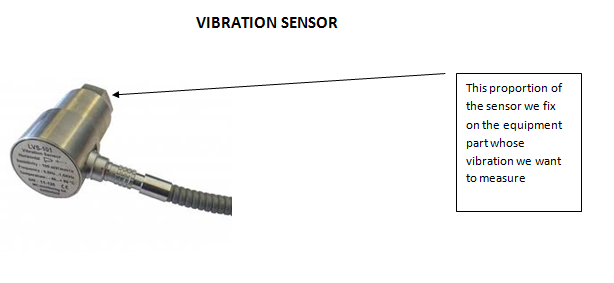

VIBRATION

SENSOR

Vibration

sensor is used to determine the vibration of any equipment. The abnormal

indicative of problems with an industrial machine can be detected and repair

before the event of machine failure because such failure is potentially costly in terms of cost and productivity. The vibration measurement allows the

industrial plant to increase efficiency and save money

Working

The

working of the vibration sensor is based on the LVDT provided inside the sensor

As

there is vibration in the equipment on which it is installed the displacement

occur in the LVDT due to which signal is generated.

The

signal is proportional to the vibration generated. These signal is send to the DCS or to the

interlocking devices.

IN

ACC JAMUL WE MAINTAIN THE VIBRATION UP TO 8mm/sec

VIBRATION

SENSOR

ZSS(Zero speed switch)Zero speed is used to sense to sense the motion of the belt conveyor, bucket elevator .

Output pulse from proximity sensor come to ZSS. If the

pulse from the proximity sensor don’t come it trip the circuit and power will

get cut from the driving motor

There is three setting is given in the zss

SPEED

The speed range is selected according to

the pulse output coming from proximity for each revolution of drive we want to measure .

IBPD

IBPD is define as the initial by pass

delay. The rotating device as initially has zero speed initially so the proximity generates no pulse so the motor get

trip in the starting and motor will not get started so IBPD is given in the ZSS

to give the bypass to ZSS at starting

TRIP

As in the conveyor or bucket elevator a

material get stuck we do not trip the motor immediately so we give the trip

setting to the ZSS for few second so we adjust the trip up to 10 sec to trip

the motor